New, more detailed etch rates for metals using Multi-Etch

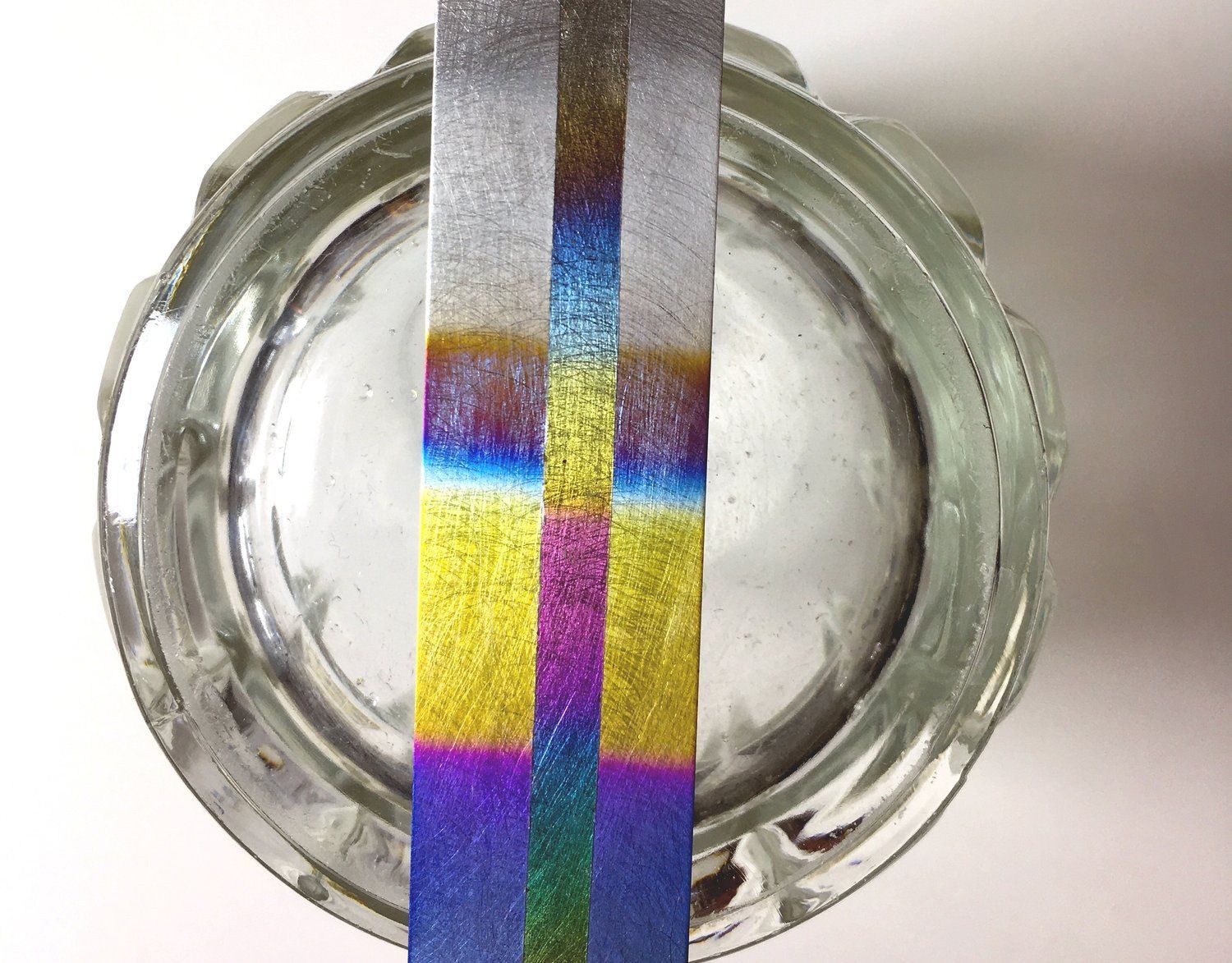

Strips of anodized titanium using room-temperature Multi-Etch.

Happy Spring from Multi-Etch!

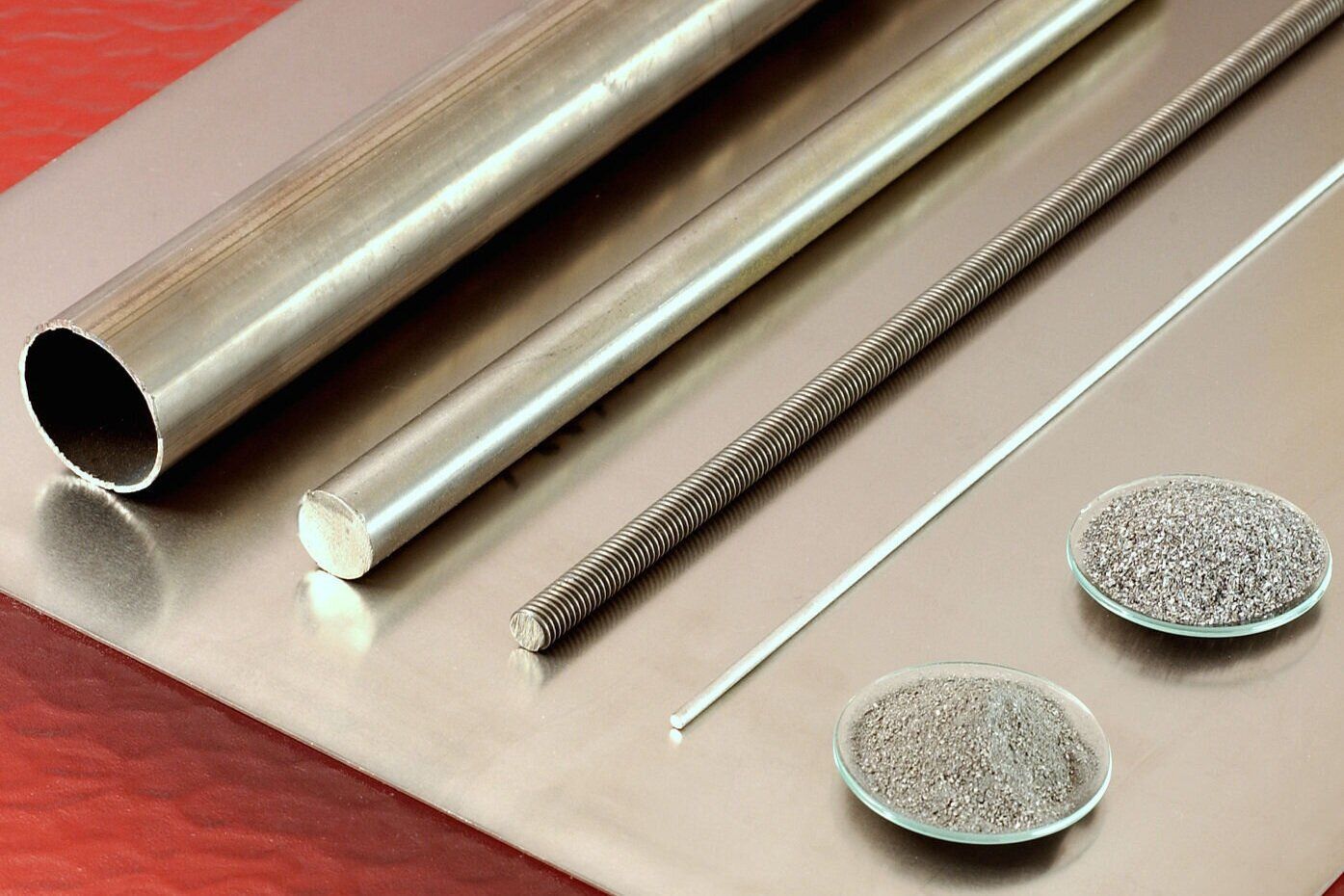

We've been experimenting with Multi-Etch and have some new data to show for our efforts. We tested heated as well as room temperature Multi-Etch on additional grades of titanium and on NiTiNol and retested many metals we did in the past.

If your procedures are working for you, there's no need to change anything.

We did find that room-temperature, double strength Multi-Etch, after having been activated by heating it one time, etches more quickly than we thought. When prepping for anodization or welding, we recommend starting at two minutes instead of ten.

We also measured metal removal rates with more accurate equipment and have improved data as a result.

View our comprehensive etch rates for titanium or our index of etch rates for other metals — these also include information for using Multi-Etch as a cleaner or to remove debris from some metals, and to remove anodized colors on reactive metals.

Above, you can see the results of testing grade 4 titanium strips for anodizing and welding prep in room-temperature Multi-Etch. We etched for varying amounts of time, from 30 seconds to 5 minutes. You’ll notice that the high voltage pinks look great!

We hope this information is helpful to you, and again want to let you know that if your current methods are working there is no reason to change.

Keep on etching!

SIGN UP FOR NEWS AND INFORMATION

We will get back to you as soon as possible.

Please try again later.